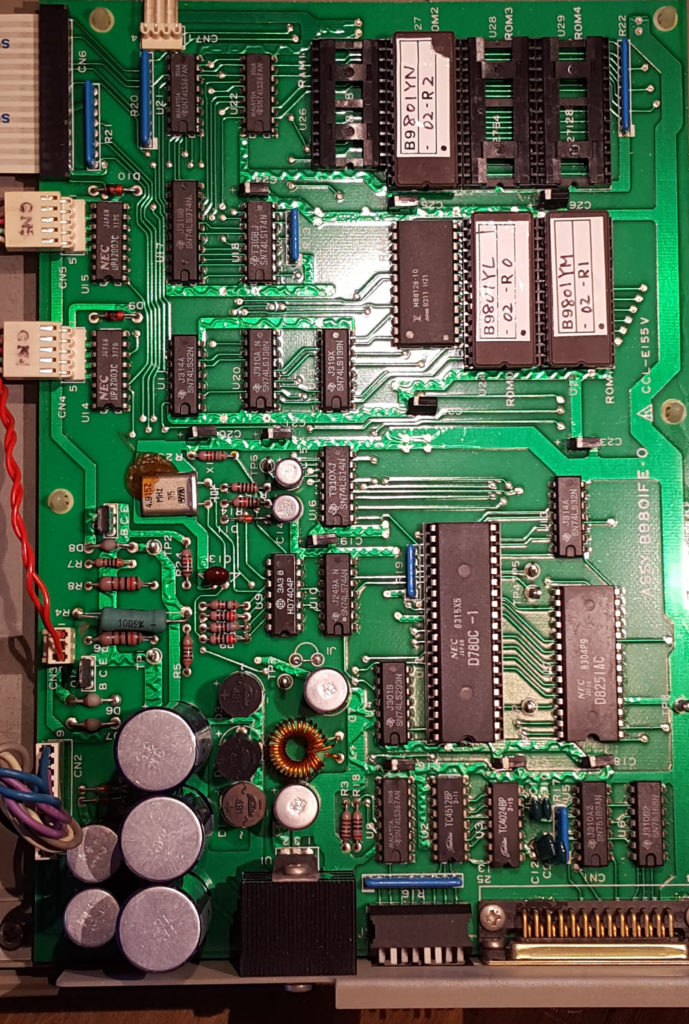

My favorite artifacts to extract from an old ROM dump are the fonts. For old 80’s-era computers and control equipment, these are usually 1-bit raster fonts covering the ASCII character set. Sometimes, the fonts are even encoded on their own ROM and accessed directly by the video generator logic; old terminals and displays will often take this route, allowing the device to be modified for markets that use different character sets by just swapping one chip. Other systems embed the font in the same ROM as all the other logic.

Finding these fonts is trivial– you usually just have to render the ROM as a 1-bit bitmap and look for the text. A small throwaway python script is sufficient to extract them and generate a bitmap font.

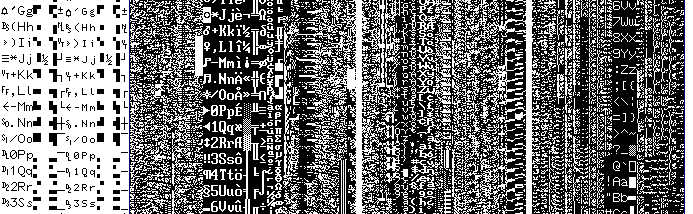

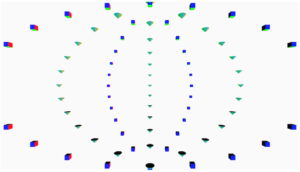

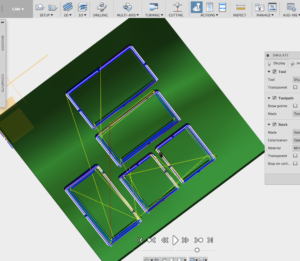

From left to right: the fonts from an AT&T 3B2, a Compaq Portable III, a LED scrolling sign, and a Waters 600E pump controller

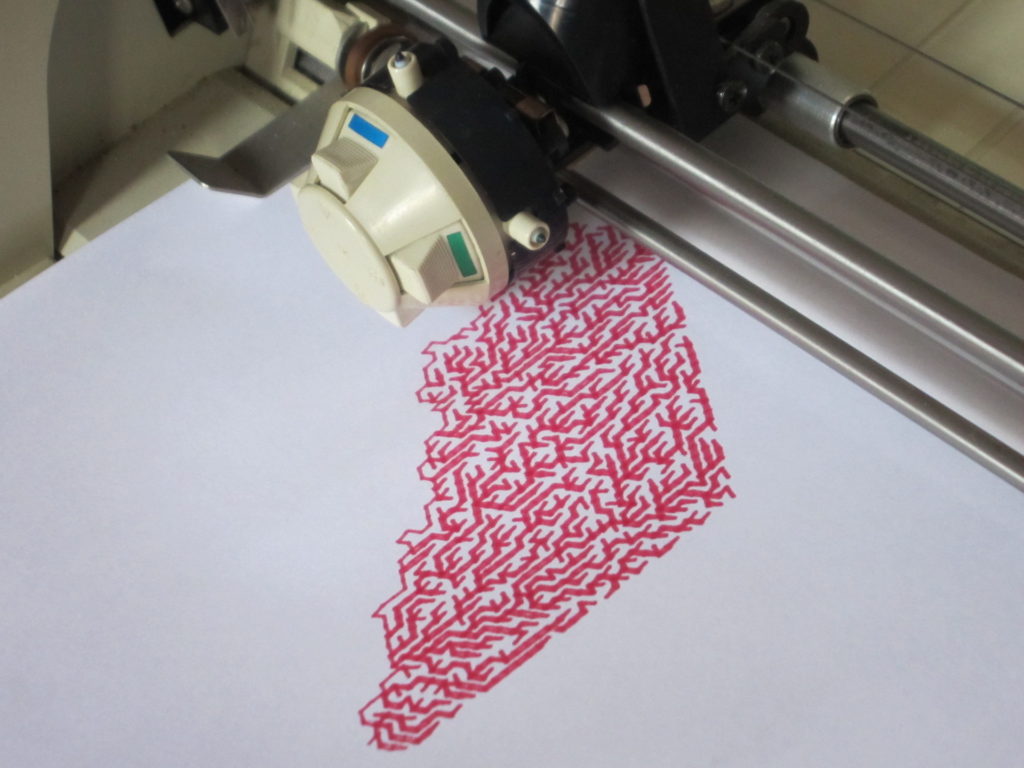

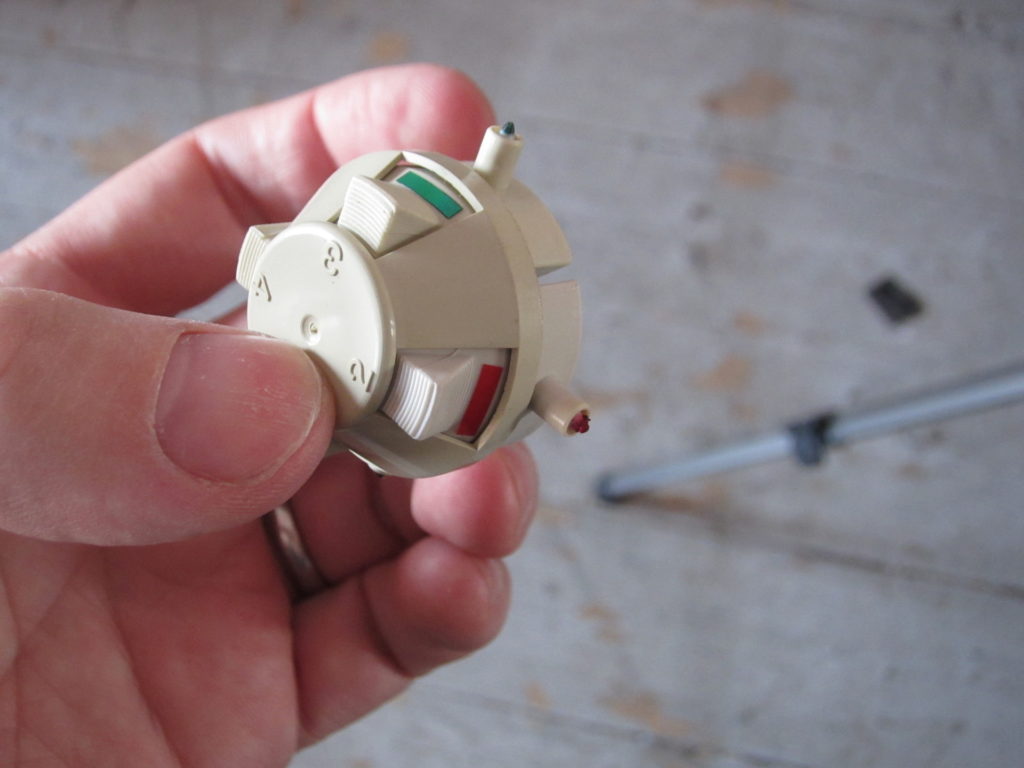

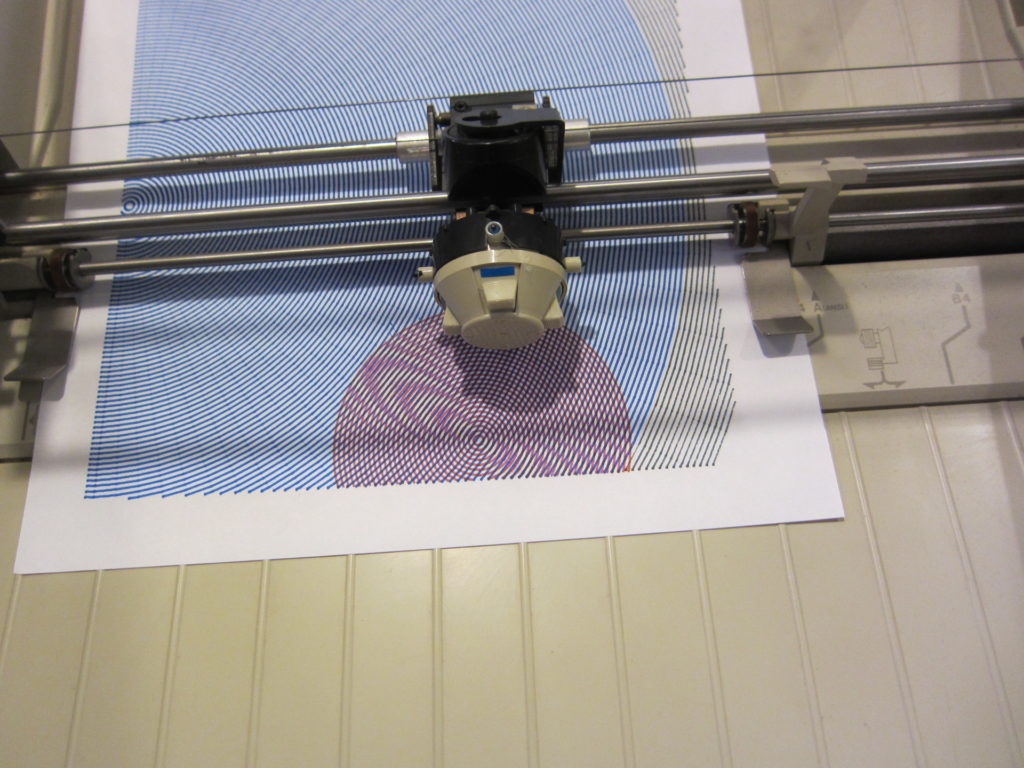

Extracting the font from the Apple 410 Color Plotter is an entirely different can of worms. For one thing, it’s a vector font– each character is described as a series of pen movements, instead of a bitmap. That means rendering the ROM as an image won’t help me; the font is a set of code snippets, not images. For another, this is 1983, storage space is limited, and there aren’t any real standards for this sort of thing. That means I’m looking for code that I don’t understand and, when I find it, won’t recognize.

There are a few approaches I can use here. A bunch of them will turn out to be dead ends, but I’ll document them as I go to help folks understand how to work something like this out for themselves.

First of all, I start by listing what I actually know about the vector font and how it’s processed:

- It’s somewhere in my ROM dump; there’s no dedicated vector drawing chip or mystery blob on this board.

- The ROM is spread across three physical chips on the board.

- The processor on board is a Z80 (an instruction set still in use in some microcontrollers!).

- Most of the ASCII character set is represented in the font.

It’s not much to go on, but it’s a start. The first thing to do is just look at the ROM with a hex editor and see what I can see.

Approach 1: Look for text

When you don’t know what you’re looking for, the first thing to look for is ASCII. This is how I found the test script; by scrolling through the ROM in emacs. The standard UNIX utility strings does a good job of finding human-readable strings in a binary. In this case, the hope would be that the vector format would be human-readable, or even in the same format that the plotter uses to receive commands from the host. No such luck; all I can find is the test script.

Approach 2: Disassemble and find the garbage

The next thing to try was to disassemble the binary and try to find regions of “garbage” instructions that are likely to actually represent data, not code. I used the venerable dz80 disassembler to try and narrow down the search a bit. To give you an idea of what we’re talking about, here’s a disassembled region that’s almost certainly data:

nop ;0187 00 .

ld b,b ;0188 40 @

sbc a,h ;0189 9c .

ld c,000h ;018a 0e 00 . .

nop ;018c 00 .

ld d,b ;018d 50 P

jp l0011h ;018e c3 11 00 . . .

nop ;0191 00 .

inc h ;0192 24 $

This has a lot of the hallmarks of garbage code– lots of NOPs, commands that follow one another that operate on unrelated registers, unreachable code following unconditional jumps. By contrast, working code looks more like this:

push hl ;0243 e5 .

push ix ;0244 dd e5 . .

push iy ;0246 fd e5 . .

ld hl,l120fh ;0248 21 0f 12 ! . .

jp (hl) ;024b e9 .

l024ch:

pop iy ;024c fd e1 . .

pop ix ;024e dd e1 . .

pop hl ;0250 e1 .

pop de ;0251 d1 .

pop bc ;0252 c1 .

pop af ;0253 f1 .

ei ;0254 fb .

ret ;0255 c9 .

Here we’re doing rational things like pushing registers to the stack and popping them in reverse order when we’re done, enabling interrupts before returning from a subroutine… it’s likely that this is part of an interrupt handler. There are no nops, registers are used after they’re modified, etc.

This helped a bit, but there was enough nonsense code (and enough obscure working code) that all this approach really got me was the ability to rule a few regions of the ROM out. Let’s try something a little more directed.

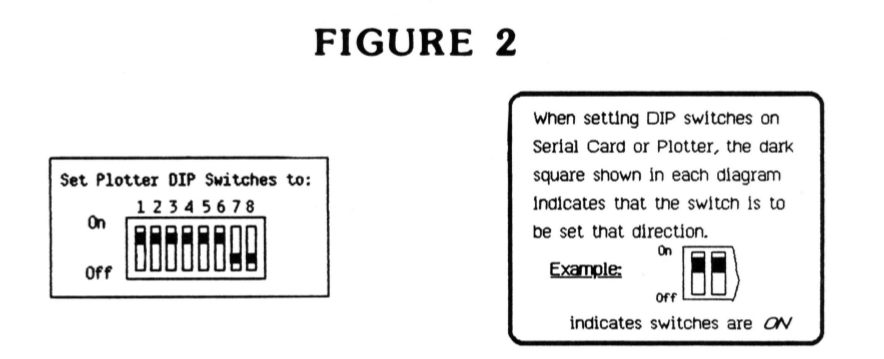

Approach 3: Look at the chip starts

As mentioned before, it often makes sense to put your fonts, strings, and other localized data on a single chip, so you only have to swap one IC to ready a unit for a different market. With this in mind, I took a quick look to see if I could find anything special at the starting points of the different physical ICs (at 0x0000, 0x2000, and 0x4000) in case the designers had taken this approach. I came up completely empty here, except for this tantalizing function at the start of 0x4000:

push bc ;4000 c5 .

push de ;4001 d5 .

push hl ;4002 e5 .

l4003h:

ld a,b ;4003 78 x

cp 048h ;4004 fe 48 . H

jr z,l4026h ;4006 28 1e ( .

cp 056h ;4008 fe 56 . V

jr z,l402bh ;400a 28 1f ( .

cp 043h ;400c fe 43 . C

jr z,l4030h ;400e 28 20 (

cp 055h ;4010 fe 55 . U

jr z,l4035h ;4012 28 21 ( !

cp 044h ;4014 fe 44 . D

jr z,l403ah ;4016 28 22 ( "

cp 041h ;4018 fe 41 . A

jr z,l403fh ;401a 28 23 ( #

cp 050h ;401c fe 50 . P

jr z,l4044h ;401e 28 24 ( $

or a ;4020 b7 .

l4021h:

ccf ;4021 3f ?

pop hl ;4022 e1 .

pop de ;4023 d1 .

pop bc ;4024 c1 .

ret ;4025 c9 .

This is pretty interesting– it’s loading a value in the accumulator and then comparing to the ASCII values for ‘H’, ‘V’, ‘C’, ‘U’, ‘D’, ‘A’, and ‘P’. It sure looks like it’s parsing an ASCII character! Unfortunately I didn’t see these characters appearing in any quantity in the rest of the ROM, so whatever it’s parsing, it’s not an on-chip font. Let’s try something else.

Approach 4: Monotonically increasing values

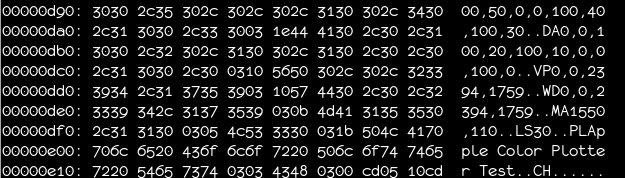

This approach involves making a few more assumptions about how the original designer was going to encode the vector font. The first is that they’re unlikely to toss all the drawing commands into the ROM at random; they will probably appear one after another in an orderly fashion. The second is that, since some characters are more complex than others (and we’re trying to save space!), they won’t just be in a table with fixed-width entries. That means that in order to find the character drawing instructions, there will have to be a lookup table somewhere in the ROM. Now, if that lookup table is organized sequentially by ASCII code, and the character instructions also appear sequentially in the ROM– and although they don’t have to, why wouldn’t they?– we can look for a sequence of monotonically increasing numbers, probably 16-bit addresses, that are separated by small but varying amounts. And, scrolling through the raw hex, we come across that exact thing around 0x2560:

00002560: 6dc1 cd09 25c9 205f 4827 2628 2631 263a m...%. _H'&(&1&:

00002570: 264b 265e 2671 2680 2685 268e 2697 26a2 &K&^&q&.&.&.&.&.

00002580: 26aa 26b3 26b8 26c0 26c5 26d1 26d9 26e4 &.&.&.&.&.&.&.&.

00002590: 26f4 26fb 2607 2716 271d 2730 273f 274e &.&.&.'.'.'0'?'N

000025a0: 275e 2764 276d 2773 2782 2795 279e 27ad '^'d'm's'.'.'.'.

000025b0: 27b8 27c2 27cc 27d5 27e2 27eb 27f4 27fe '.'.'.'.'.'.'.'.

000025c0: 2707 280d 2815 281c 2828 2832 2842 284e '.(.(.(.(((2(B(N

000025d0: 285d 2864 286d 2873 287b 2883 288b 2892 (](d(m(s({(.(.(.

The xxd utility is doing us a disservice here by arbitrarily inserting spaces between values at 2-byte intervals. It’s tempting to think this table starts around 0x256A with the values 0x2628, 0x2631, 0x263a… but it’s a mirage. If that alignment were correct, then a bit later we’d come across the sequence 0x26f4, 0x26fb, 0x2607, 0x2716… which doesn’t make much sense. What’s actually happening here is that the 16-bit values start at 0x2569, and are little-endian– the small half of the value comes first. Once we interpret it that way, the numbers are monotonically increasing like we’d expect.

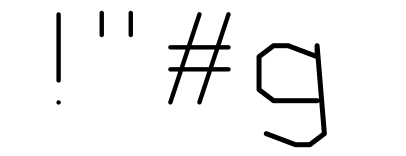

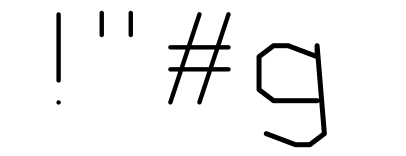

Now let’s look at the values themselves. The first few values are 0x2627, 0x2628, 0x2631, 0x263a, 0x264b. That means the lengths of the first four entries are 1, 9, 9, and 17. The first four printable ASCII characters are SPACE (no strokes), ! (two strokes), ” (two strokes), and # (four strokes)… it looks like we’ve found our font!

Decoding the vectors

Now it’s time to look at the actual data pointed to at the table. Again, taking the first few characters, we have:

SPACE ff

! 01 08 21 02 01 00 21 00 ff

" 01 28 21 26 01 68 21 66 ff

# 01 00 21 48 01 88 21 40 01 83 21 03 01 05 21 85 ff

It’s pretty clear what’s going on here: 0xff is the end-of-character delimiter (so the SPACE character, reasonably enough, draws nothing). Each stroke consists of a sequence 01 AB 21 CD, so we can think of 01 as indicating a “move to” command, and a 21 as indicating a “draw to” command. That only leaves one byte to indicate an X/Y coordinate. As it happens, this is all we need: the high four bits of the byte indicate the X coordinate, and the low four bits indicate the Y coordinate. We’re limited to points on a 16×16 grid, but that’s sufficient for a plotter font like this. (Keep in mind that the raster fonts above are often 8×10, and they don’t have the benefit of being able to draw smooth lines between points.) It’s also fair to assume that these are signed four-bit numbers; for instance, a Y value of 0xf indicates a point one unit below the baseline.

Later on, we find sequences like this:

% 01 47 24 28 07 26 47 01 88 21 00 01 41 24 60 81 62 41 ff

This is made up of three strokes, but the two circles in the ‘%’ sign are drawn as small squares. Instead of the draw-to sequence starting with 0x21, these sequences start with 0x24. It’s clear that 0x2X codes represent a sequence of draws, with the X representing the number of points to draw to (in this case, 4).

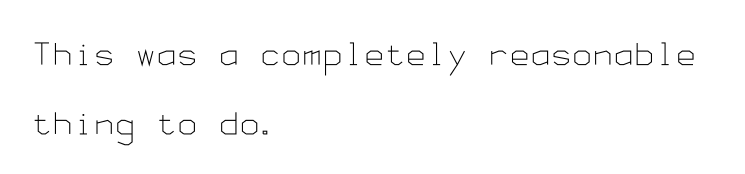

I wrote a quick python script to render these characters as SVG to see if this hunch was correct, and it worked perfectly– or almost.

good good good oof

For some internal reason I’m not entirely sure of, points with a Y coordinate below the baseline are offset by one X unit. This is probably related to how they implemented the packing/unpacking algorithm (probably allowing the Y value to overflow into the X coordinate). Anyway, I put a quick fix in the python extraction script and we were good to go.

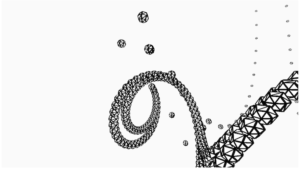

Building the TrueType font

I set up the python script to go through the font and generate an SVG file for each character. The only remaining problem was to create a valid TrueType font from these characters. Luckily, the fontforge tool is scriptable in python, so I was able to whip up a small script to generate the TT font. Less luckily, fontforge’s SVG import is very unstable, so I had to do a lot of manual cleanup, but eventually I was able to generate something renderable.

And here it is. It’s monospace, so you can use it as your terminal font, if you like, and you’re completely nuts. Not like me, an ordinary human who is definitely sane.

Postscript

The next step is to integrate the font into my plot-to-svg script. This should let you experience all the fun of having an Apple 410 without the frustration and maintenance issues of having an Apple 410, and at a fraction of the cost!

Also, a big thank you to Matthew Blain who was able to find a copy of the Apple 410 manual and complete the documentation for the remaining functions!