Andrew O’Malley

Hacker in Residence @ NYCResistor, Summer 2010

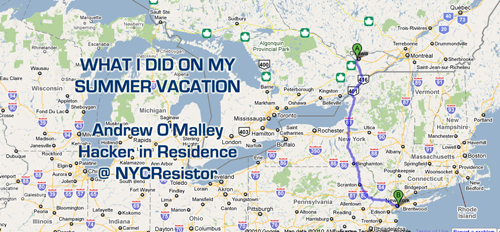

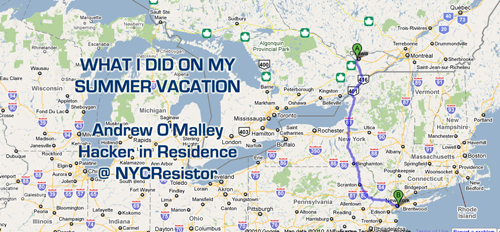

Hi, I’m Andrew O’Malley, a Canadian new-media artist with a formal background in Electrical Engineering. Back in July, my wife, Deborah, and I relocated from Ottawa, Ontario to NYC for the summer, and the kind folks at NYC Resistor graciously opened up their space to me as “hacker/artist in residence” for July and August.

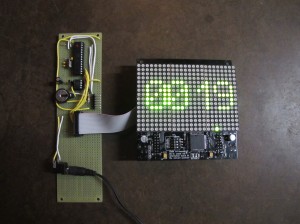

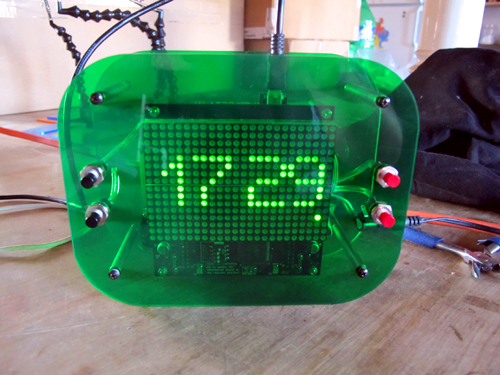

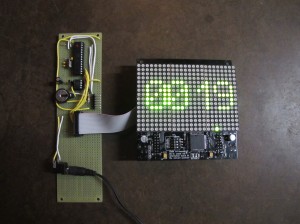

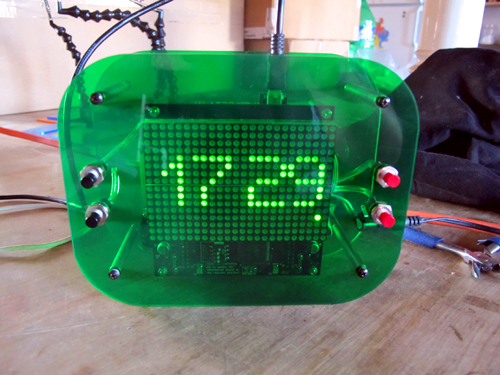

Before arriving in NYC, I spent a busy spring developing a line of decorative, animated light boxes built into wood and acrylic enclosures. Some were based around LED screens from Sure Electronics populated with retro video game animations and random drawing algorithms:

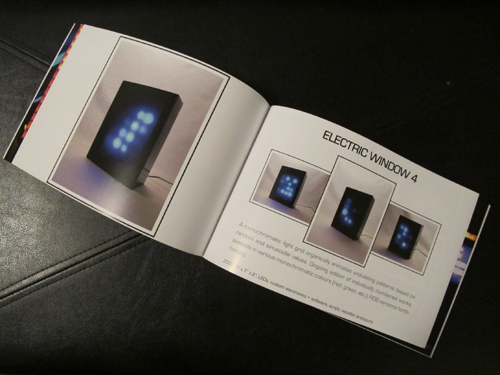

While others featured diffused grids of LEDs driven with sinusoidal and random algorithms:

I set up a shop at Makers Market and have been selling these boxes on-line since the spring of this year. A primary goal of my time this summer was to further this line of fixtures with an open-source clock kit featuring multiple animations for displaying the time both literally and abstracted. Working with NYCResistor was a perfect pairing for this project thanks to their extensive electronics resources/tools, and fabrication tools – Tool Town and the laser.

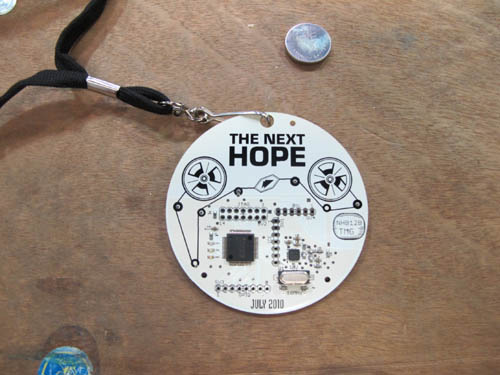

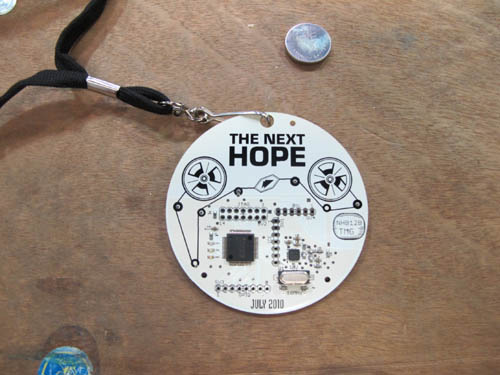

Before setting to work on the clock project, however, a great “distraction” arrived in town in the form of The Next Hope.

The conference and energy of all the attendees was inspiring, and really deserves a blog post of its own. In short, it was a great way to get my gears going. Even the badge was memorable:

I didn’t get a chance to do any badge hacking, but was thoroughly impressed with Adam Mayer’s “doppelganger” firmware which cloned and rebroadcast the id of nearby badges . . .

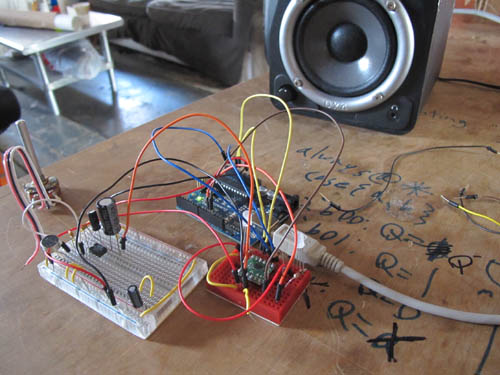

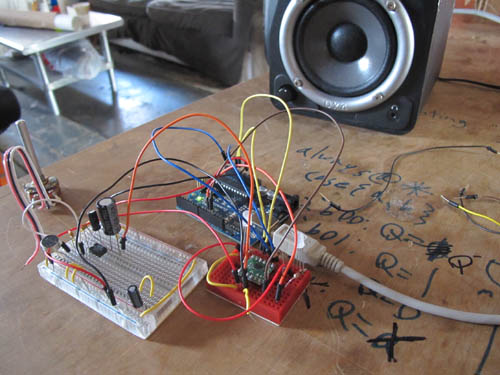

Back at Resistor headquarters, my clock screens had yet to arrive so I turned my attention to a few other random projects. The first was hacking the Disco Chip, a break-out board from Rachel’s Electronics in NYC.

The Disco Chip takes a mic or line input, and drives an RGB LED to the low, mid, and high frequencies of the input audio, most likely to drive keypad backlights in mobile phones. I’d like to take advantage of all that small footprint filtering to control more LEDs, or anything else for that matter, so I worked on sampling the LED drive signals into the analog inputs of an Arduino. Thus far I’ve had average results, and need to spend more time finessing the system. I’ll soon be writing a detailed post about this for my project blog.

In the meantime, an Ottawa-based deadline was creeping up on me so it was onto another project, and thankfully some of my LED screens had arrived:

The above piece was for a charity art auction called “Portraits of Bluesfest 2,” and featured two 24×16 LED screens displaying random Tweets mined from Twitter.com during the Ottawa Bluesfest in July. I won’t repeat the whole back story on this one, which you can read here. This project proved a great opportunity to finally fire up NYCR’s laser cutter and make something pretty.

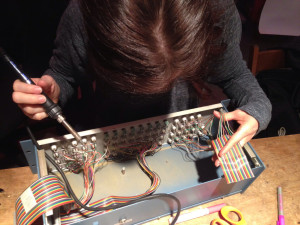

By this time, I’d accumulated all the parts I needed to get started on the clock project, so I soldered up a prototype:

Adafruit has a nice tutorial on the DS1307 RTC chip, so I had a simple clock up and running pretty quickly.

Next it was back to the laser cutter to fire off a nice little enclosure:

Here’s a video showing a few of the animations I’ve programmed so far:

DOTKLOK prototype preview from The Latest Artists on Vimeo.

The final kit should be ready sometime in October, and will most likely feature a black and smoked acrylic case, with the choice of a red or green LED screen. I’m going to source some classier buttons, but their position remains undecided: along the bottom, or on the sides? I’d love to hear people’s preferences on button placement, please share your thoughts in the comments!

I think I became what they call “laser crazy,” as I started another project based on my access to the laser cutter. This one is a multi-panel, edge-lit design, depicting the iconic New York subway map, with a different colored subway line on each panel:

This piece is destined for an annual show back in Ottawa called Candela, dedicated to light as an artistic medium. Here’s the formal proposal for the project which describes the entire piece, including an animated simulation written with Processing.

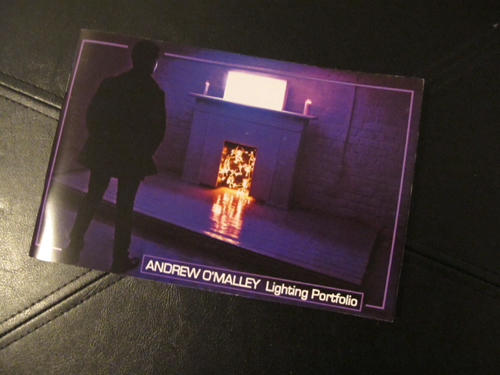

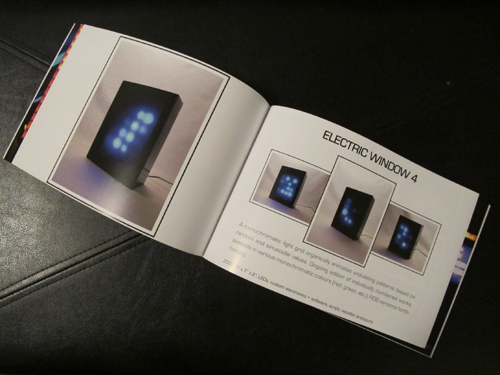

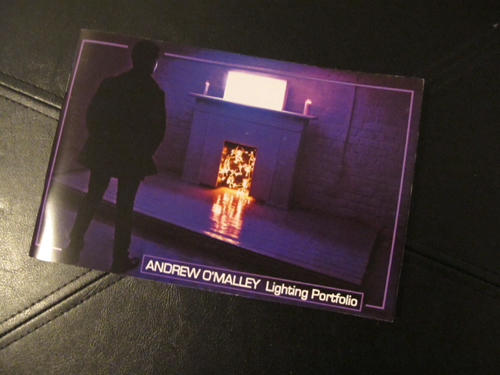

I had a few projects on the go outside of Resistor headquarters as well. Deb and I were able to use our mutual free time in NYC to put together a hardcopy portfolio showcasing a bunch of my previous lighting projects:

You can check out a softcopy here.

All the credit for this one goes to Deb and her awesome graphic design skillz. For printing, we used a web-based service called Smartpress and were really happy with the cost and quality.

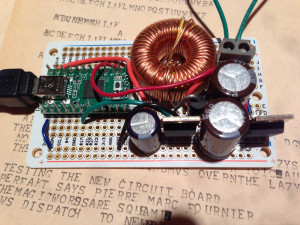

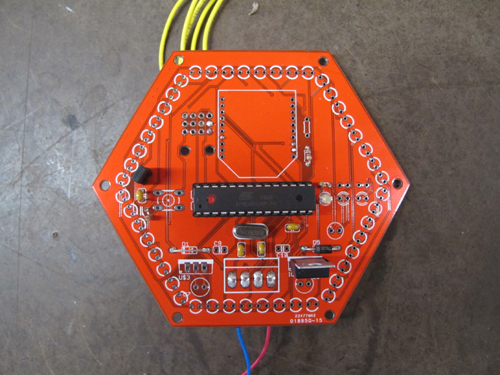

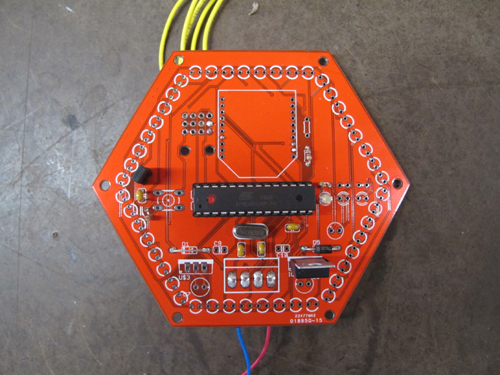

Lastly, I interned with Hernani Dias during his residency at Eyebeam Art + Technology Center to develop some hardware for his ReFarm the City project. Specifically, I designed an LED board for remote data visualization. Here’s a pic of the partially soldered board:

The board features an Atmega168 running the Arduino bootloader, wirelessly updateable via XBee, for controlling 48 Charlieplex’d LEDs. Serendipitously, days before being asked to design this board, I learned about the LOLShield at The Next HOPE conference, so a big thanks to Jimmie P. Rodgers and his documentation which schooled me in the art of Charlieplex’ing.

Speaking of thank you’s, I’d like to take this opportunity to thank all the members of NYC Resistor for their amazing hospitality, welcoming me into their extremely enabling and fun space. It was also especially inspiring to meet the Makerbot crew downstairs, and see them hard at work, creating and reiterating prototypes for future generations and features of the Makerbot.

I look forward to sharing some of the NYCR spirit that’s rubbed off on me with the members of Ottawa’s Mod Lab at Artengine, who just recently acquired and assembled their own Makerbot.

And of course, if any of the Makerbot or Resistor gang find themselves headed to Ottawa, Montreal, or even Toronto, make sure to give me a shout!

Thanks again,

Andrew O’Malley

www.aomalley.org

www.technoetc.net/blog

PS I’m not affiliated with Adafruit, Sure Electronics, or any of the other products or services mentioned in the above blog post, I just figure it’s handy to provide the info for anyone interested.